Hi folks, Maltesh S. here from India. I’ll be blogging for The 3DP Report giving you my perspective from the front lines as an Engineer for Wipro. As an engineer, I prefer to use the term additive manufacturing versus 3D Printing because in the manufacturing world, the word ‘manufacture’ is supreme. Certainly the term 3D Printing sounds “sexier” and it’s catchier to say, “my iPhone case is 3D printed” than “my iPhone case was created using Additive Manufacturing”, but what can I say? I’m a purist.

Regardless of the terminology we use, in my view, there are four primary hurdles the “3D Printing” industry must overcome in order to truly revolutionize manufacturing as we know it today:

1. Shift in Focus from Prototyping to Finished Products

The National Additive Manufacturing Innovation Institute (NAMII) has realized that in order for the rapid prototyping to gain acceptance, it is important to shift the mindset towards the development of functional products rather thanfocus exclusively on prototyping. An engineer wants functional components in his hand. He wants toput the part to severe tests and come out triumphant. A prototype is often nothing more than a toy, which after the day’s presentation to his bosses, he is likely to give it away as toy to his children.

The National Additive Manufacturing Innovation Institute (NAMII) has realized that in order for the rapid prototyping to gain acceptance, it is important to shift the mindset towards the development of functional products rather thanfocus exclusively on prototyping. An engineer wants functional components in his hand. He wants toput the part to severe tests and come out triumphant. A prototype is often nothing more than a toy, which after the day’s presentation to his bosses, he is likely to give it away as toy to his children.

Certainly 3D printing of prototypes plays an important role in developing certain products, but in order for a true manufacturing revolution to take place, additive manufacturing must be considered as the primary method of production rather than simply a means to design the final product.

2. Need for Proof of Concept for Functional Products

The shift to developing functional components rather than prototypes has been hindered by the lack of successful “proof of concept” examples of success. Densely written research papers are available but that’s not what the supply chain manager in a Ford engine assembly line will read during his lunch break. He would prefer a simple apples- to-apples comparison that illustrates the benefits of an additive manufactured component. In the days to come I will blog about the challenges that we have faced in working with our end customers.

The shift to developing functional components rather than prototypes has been hindered by the lack of successful “proof of concept” examples of success. Densely written research papers are available but that’s not what the supply chain manager in a Ford engine assembly line will read during his lunch break. He would prefer a simple apples- to-apples comparison that illustrates the benefits of an additive manufactured component. In the days to come I will blog about the challenges that we have faced in working with our end customers.

3. Designers Must Embrace the Freedom that Additive Manufacturing Enables

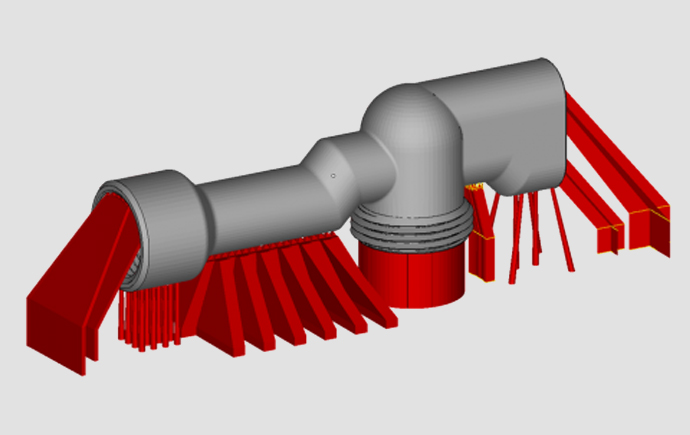

It doesn’t make sense to replicate a component that can easily be manufactured using conventional methods. The beauty of additive manufacturing is that it has no design limitations and this freedom must be thoroughly exploited at every stage. Designing for 3D printed product allows for so many benefits:

- Reduction or complete elimination of material waste

- Construction of superior technical properties

- Usage of multi-materials in a single component

- Adaptation of embedded sensors and personalization to the last mile.

But so far, there have been limited attempts to bring about a design revolution. There seems to be inertia in the way a designer’s mind thinks about limitations of machining. In order for additive manufacturing to reach its full potential designers will need to jump out of their box!

4. High Cost to Scale

Finally, the costs of additive manufacturing of functional components are still too high. The economies of scale have not yet kicked in for the limited suppliers of powdered materials. But when it does, we will witness a steep reduction in the cost of additive manufactured components. For now, industries with deep pockets, such as aerospace, have been the early movers to adapt batch production. Additionally, components made of ABS material are already trending to be cheaper than conventional manufacturing where batch productions are less than 1,500 units.

Finally, the costs of additive manufacturing of functional components are still too high. The economies of scale have not yet kicked in for the limited suppliers of powdered materials. But when it does, we will witness a steep reduction in the cost of additive manufactured components. For now, industries with deep pockets, such as aerospace, have been the early movers to adapt batch production. Additionally, components made of ABS material are already trending to be cheaper than conventional manufacturing where batch productions are less than 1,500 units.

These four challenges are all intertwined and progress in one area will lead to progress in the others. There is no real start or end, but rather an ecosystem that will improve incrementally in each area over a long period of time.

Credits:

- The photographs are taken from publically available domains and published reports

- The break-even chart is part of the publically available report by Econolyst on their website (www.econolyst.co.uk)