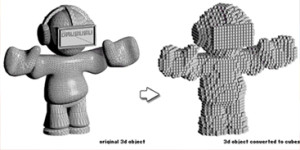

First the definition: Voxel is a 3-dimensional pixel. Its’ long form is Volumetric Picture Element. Since there is no defined dimension or shape for a voxel, any object that has repeatability in its use to render a larger object can be categorized as a voxel.

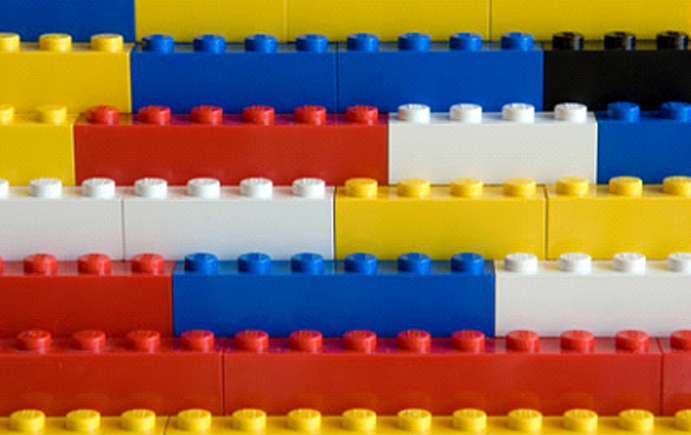

Let’s imagine Lego blocks. They are voxels that are used in everyday life. They have a defined shape and size and they can be stacked on each other and / or beside each other to ultimately render a new form. A voxel can come in the form of a square, rectangle, diamond, spherical, cube, triangle, octahedron and many more as long as they confirm to the principal rule of repeatability.

As a matter of fact, every matter is fundamentally voxel if it considered in terms of distinct, regularly repeating regions. While digitally creating a voxel model it is much the same way as a digital byte is binary – 0 or 1. The existence of each voxel within the solid must be defined as either present or not present. Voxels bring about some inherent advantages:

Take the simple case of LEGO. Children playing with it need to have an accuracy of roughly 1mm hand placement assembling accuracy. But what they finally get is a structure that has accuracy up to 5 nano meters LEGO. The end result is an object more precise than the fabricator that created it

Take the simple case of LEGO. Children playing with it need to have an accuracy of roughly 1mm hand placement assembling accuracy. But what they finally get is a structure that has accuracy up to 5 nano meters LEGO. The end result is an object more precise than the fabricator that created it- Self alignment is the second advantage. Because of their geometric structure, the voxels will self-align as long as they are placed in the right direction and within a certain distance of its final position. Thus the precision of the final part depends only on the tolerances of the voxels.

- Digital parts are perfectly repeatable with no loss of 3D information over subsequent replications – this makes designing that much easier. In addition scaling the voxel to different sizes ensures there is consistency in the design. It also helps minimize the errors. For instance if there are a large number of voxels that comprise the finished part, the overall precision of the part increases as random errors of individual voxels tend to cancel out.

- Voxels can be pre-manufactured to different sizes, with the 3D Printing machine only ensuring the binary (present –not present) accuracy of the placement. This brings out another advantage which is the multiple materials. Through this one can ensure the flow of voxels is such that a combination materials such as high-melting point metals and low-melting point polymers whose initial processing properties are mutually incompatible.

And finally along with multiple materials, one can bring in smart voxels. Through prefabrication voxels can also be pre-loaded with simple active components such as transistors, photovoltaics, microvalves, and other sensors and actuators, thereby opening the door to fabrication of complex, functional integrated systems.But with every manufacturing process there are inherent disadvantages too. - A finite resolution leads to a loss of generality in the shape that can be fabricated. It is not yet possible to use different resolution voxels within the same process and hence the final resolution is dependent on the choice that is initially made.

The binary process can be painfully slow if the voxels are complicated. Simple cubic or triangle voxels can bring in speed but they cannot always bring in high resolution. The tradeoff is important. - In my next article I will share with you the practical difficulties of using Voxel printing mechanism. Who is currently using it and how with sustained research and development voxel printing is ideal for 3D Printing electronic / smart objects.